Task:

VIGA Auto Tuning is a specialist tuning shop in south Poland that acquired an old water brake chassis dynamometer. The stock control system for the dyno was outdated and out of order. PEREK dynamometer controller were contacted to provide a cost-effective solution to get the dyno working.

Solution:

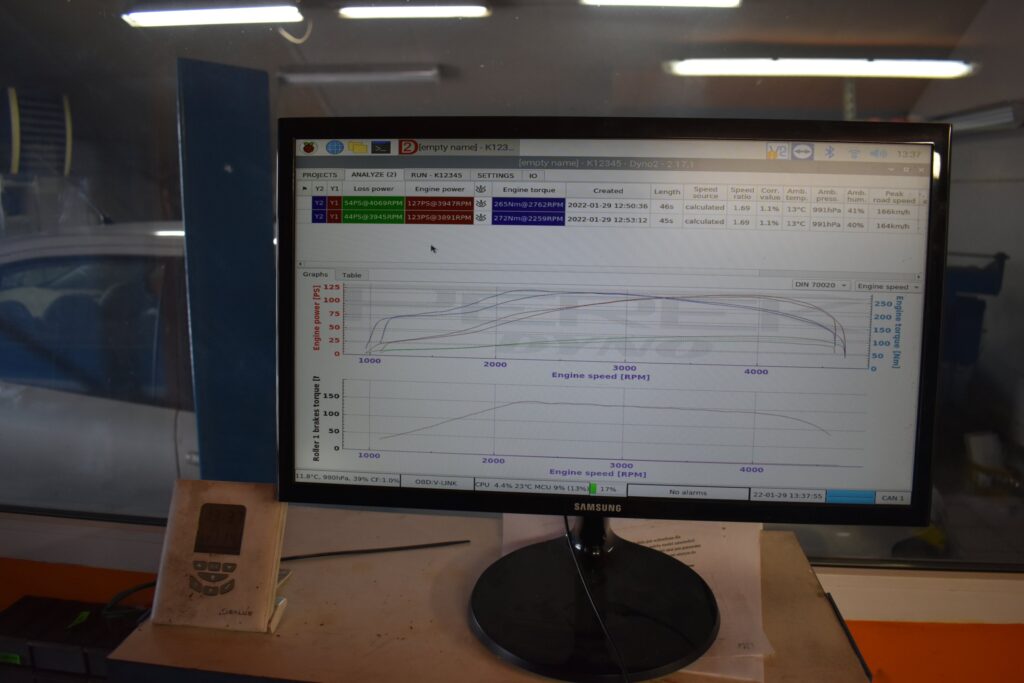

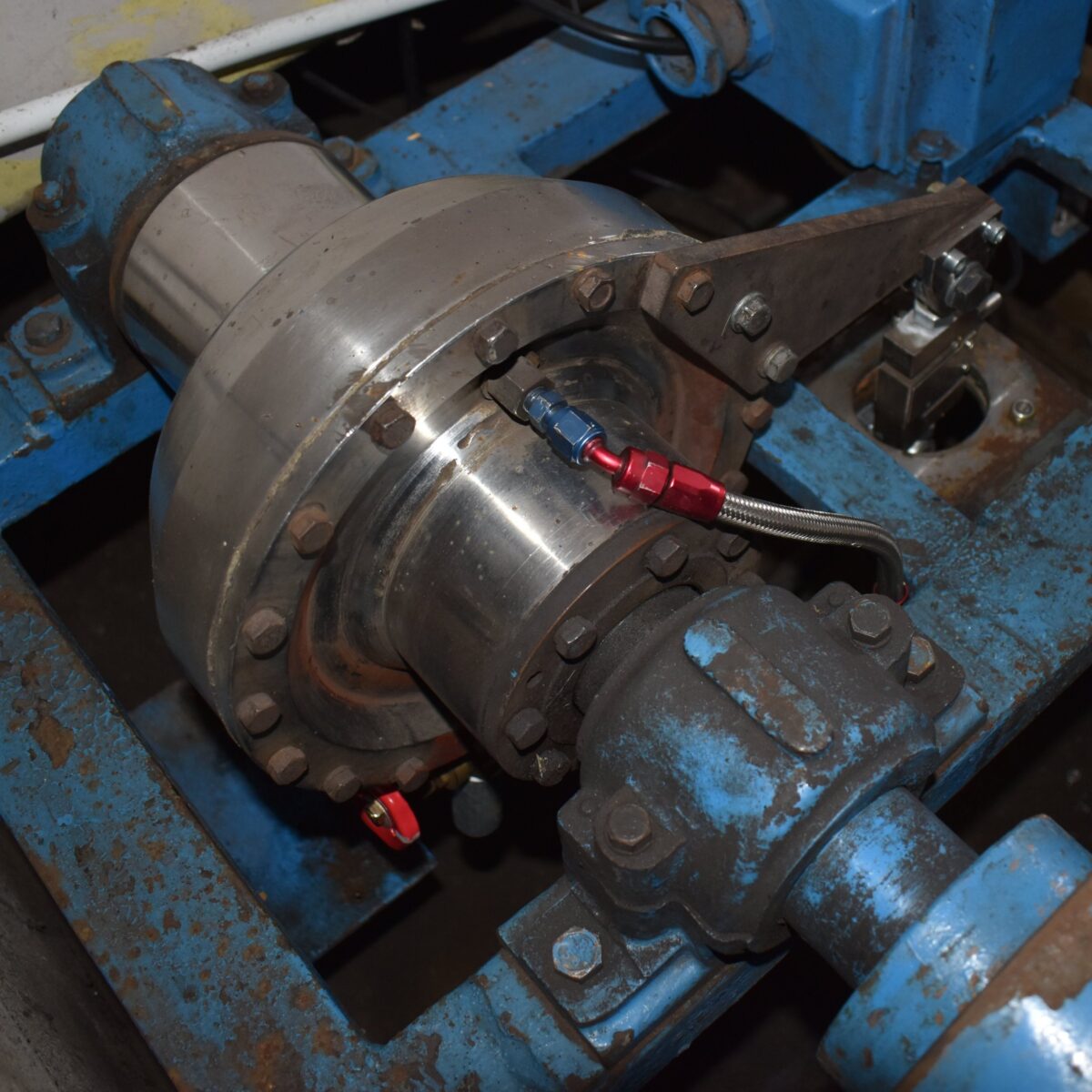

The water brake was fitted with a circuit consisting of a water pump, pressure regulator and PWM controlled inlet valve. Brake outlet uses a manual valve to control brake water discharge. Another PWM valve for water outlet is planned in future to increase the brake control speed. Dynamometer brake control and data acquisition is performed by a low cost DC1L dyno controller. The dynamometer is now capable of loading vehicles with additional torque from water brake. This allows it to be used to measure power of more powerful turbocharged cars that require additional load to spool up the turbo. Despite DC1L low cost, it is powerful enough to get the water absorber dynamometer running and still have some spare inputs for innovate AFR/lambda sensor signal and additional temperature probes.