Dyno2 was created to meet a wide range of users. It is suitable both for carrying out many hours of engine reliability tests and for short measurements to easily determine the engine characteristics. The key aspect is universality. We create Dyno2 to handle all types of dynamometers with a variety of accessories. All systems are designed transparently and allow the user to control his own settings.

The software is provided with the DC1 dyno controller without additional fees.

The key benefits of Dyno2 are:

- Support for many types of dynamometers – engine, chassis, inertial, absorber

- Programmable test sequences for maintaining engine speed and throttle control in cooperation with the Ecumaster EMU Black engine controller

- Support of a dynamometer with one or two axes with mechanical axis synchronization

- Support up to 4 eddy current brakes – 2 brakes per axle

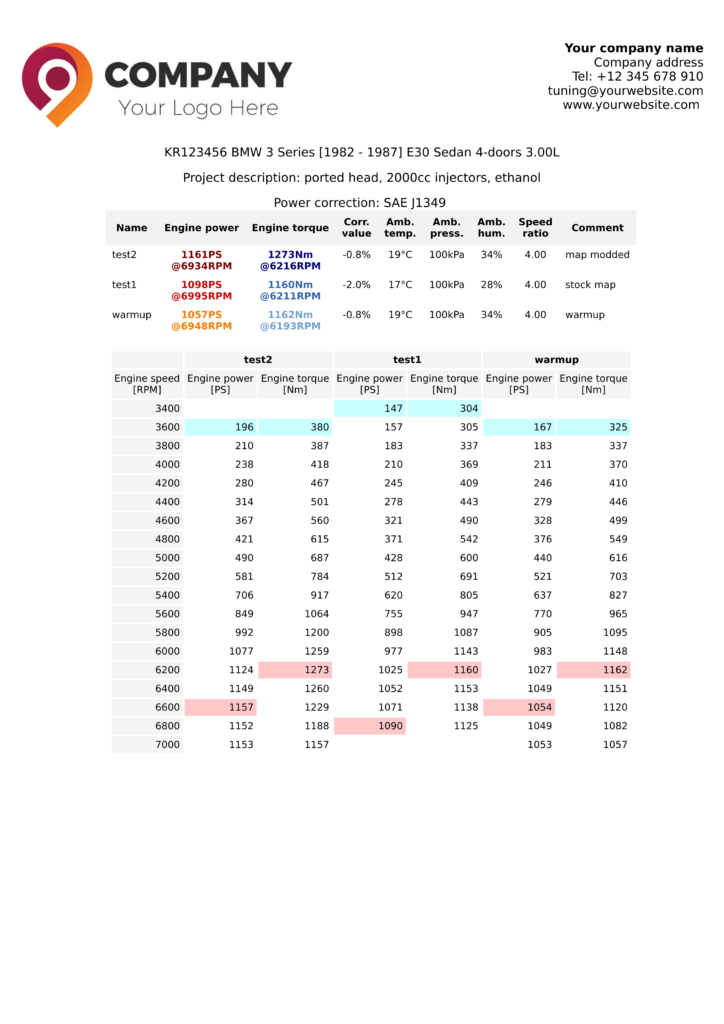

- Built-in sensor of ambient conditions (temperature, pressure, humidity) for power correction

- Support for OBD interface via Bluetooth or USB

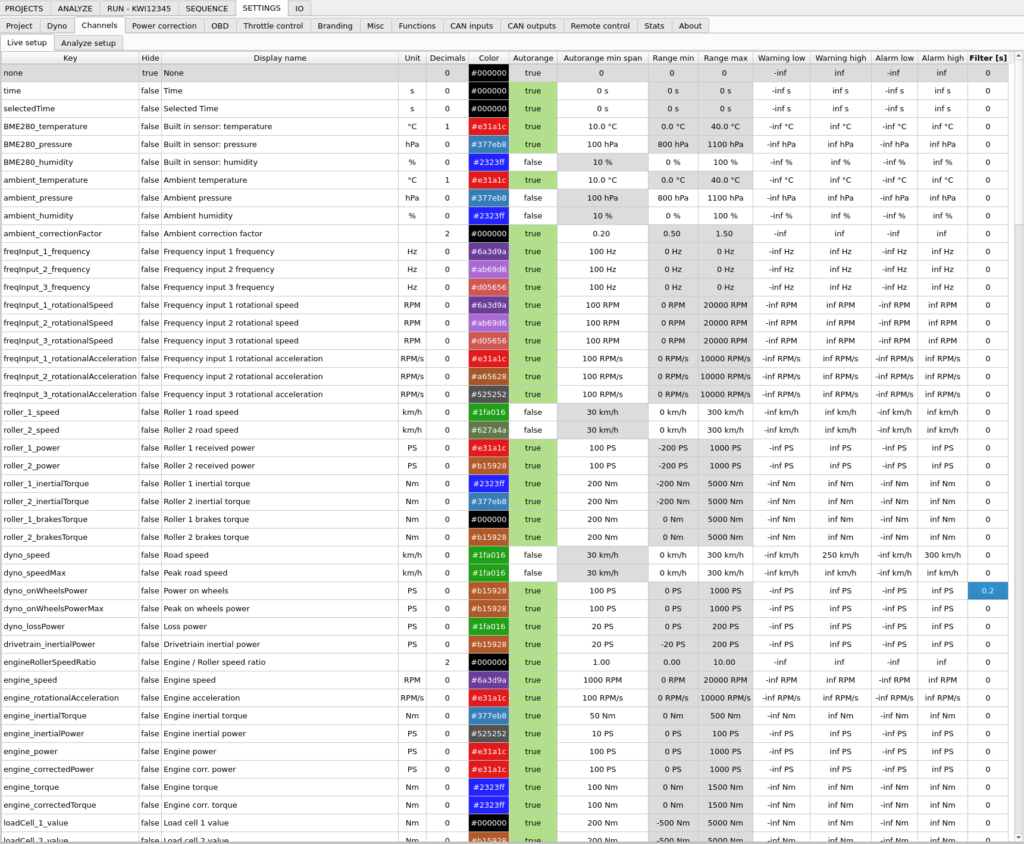

- Fully customizable software for easy support of any dynamometer

- Tools for calibration of load cells, roller inertia and brake control

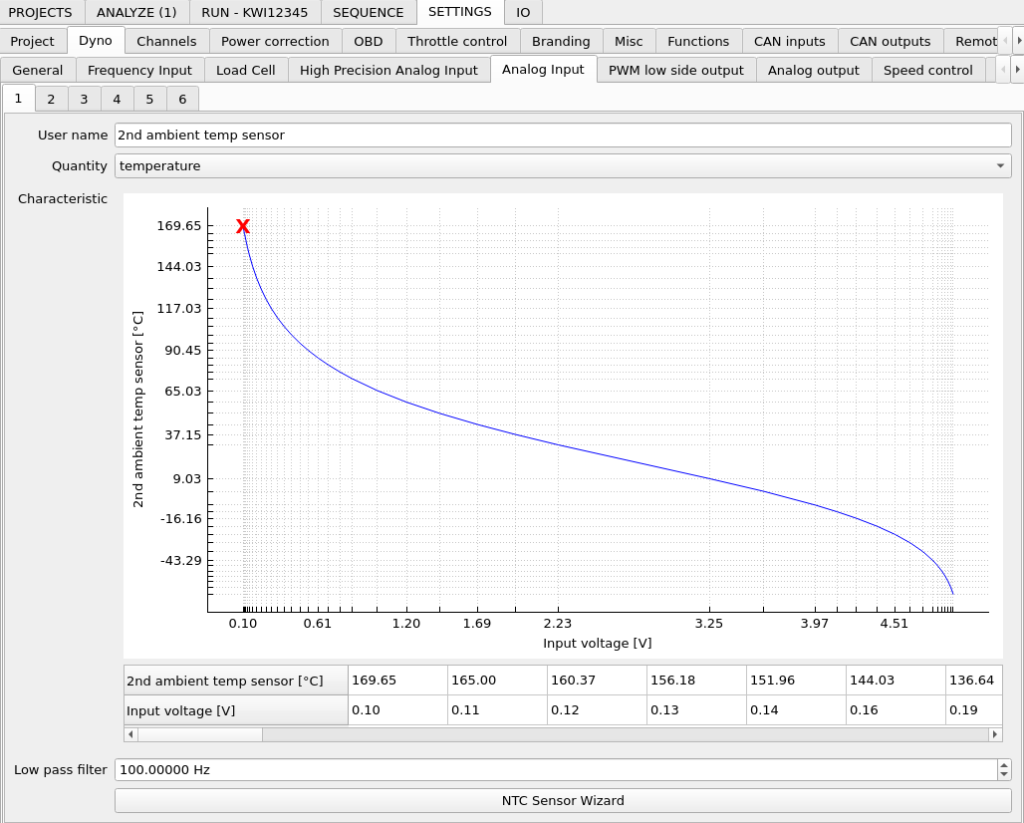

- Flexible characteristics for converting analog signals to physical quantities

- Free choice of physical units – metric and imperial

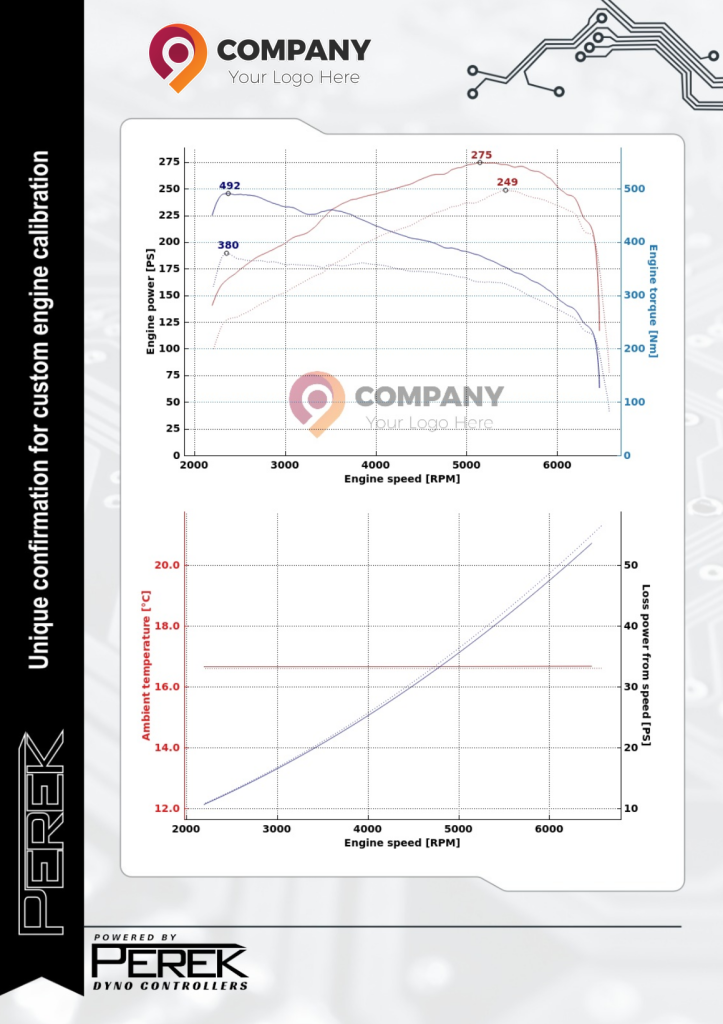

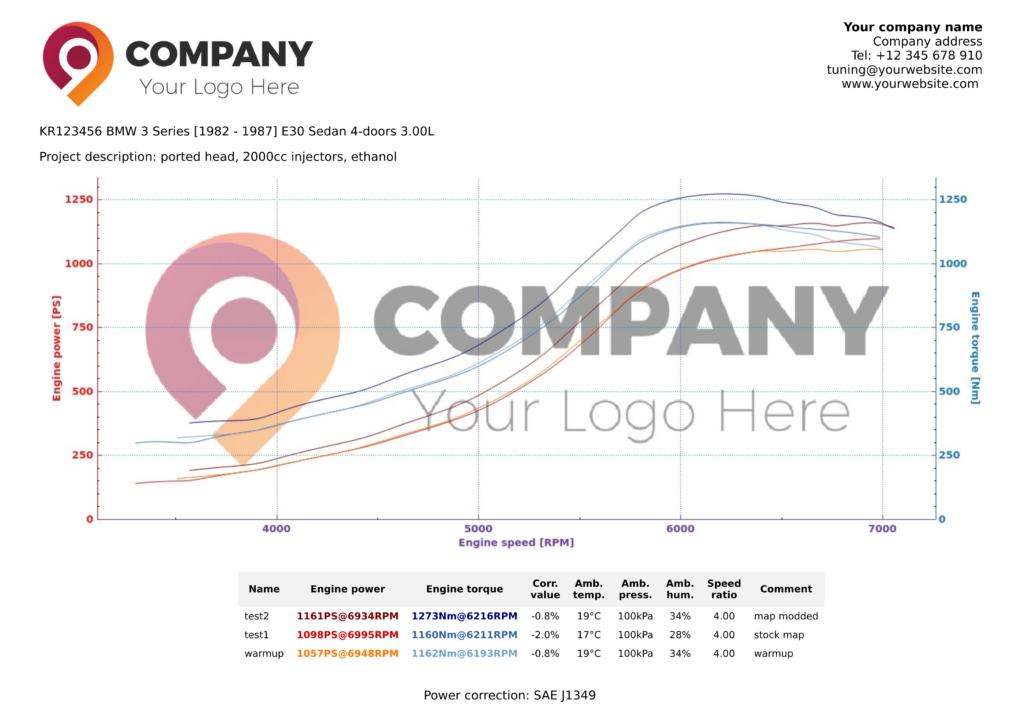

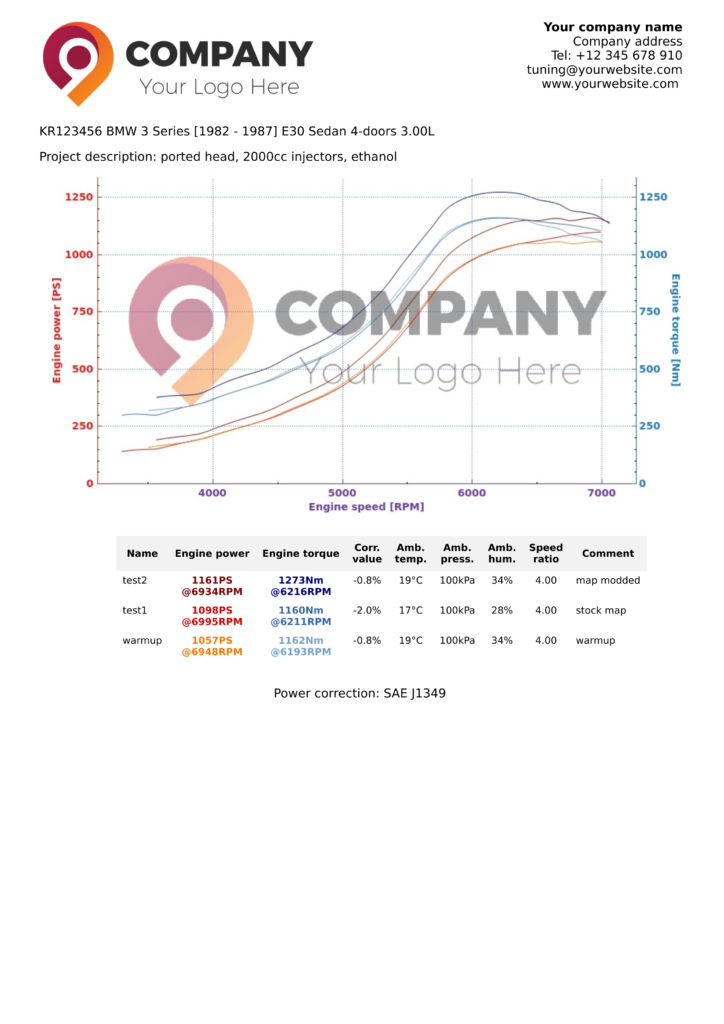

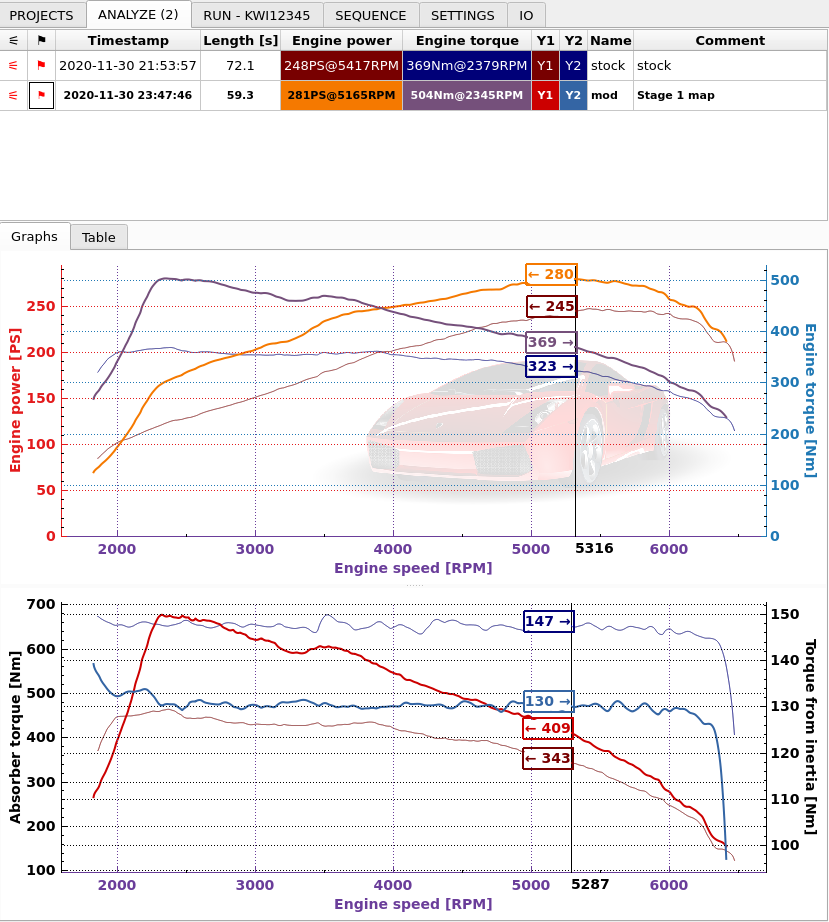

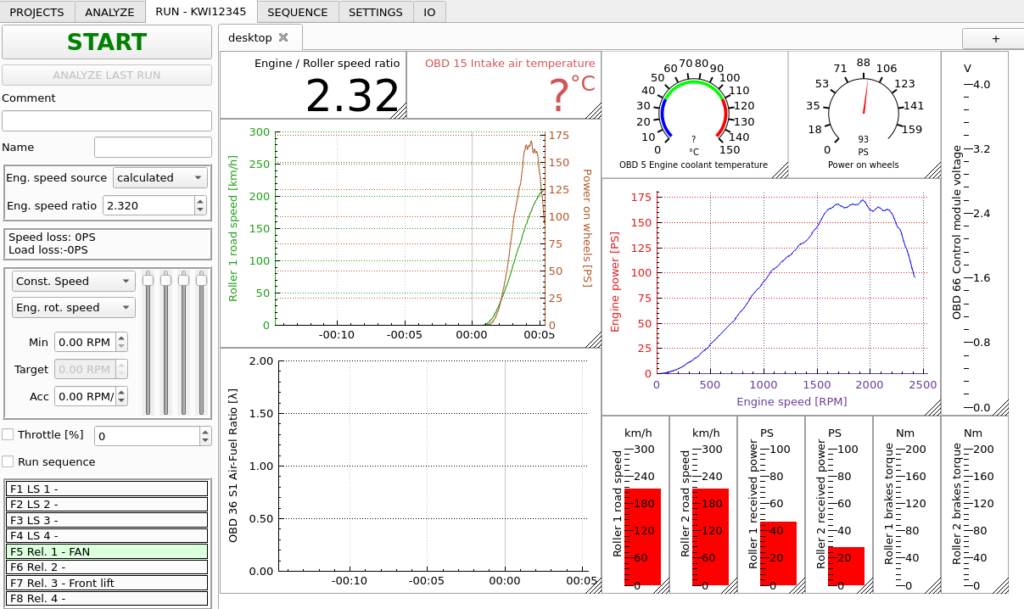

- Preview of dyno working parameters and drawing graphs in real time

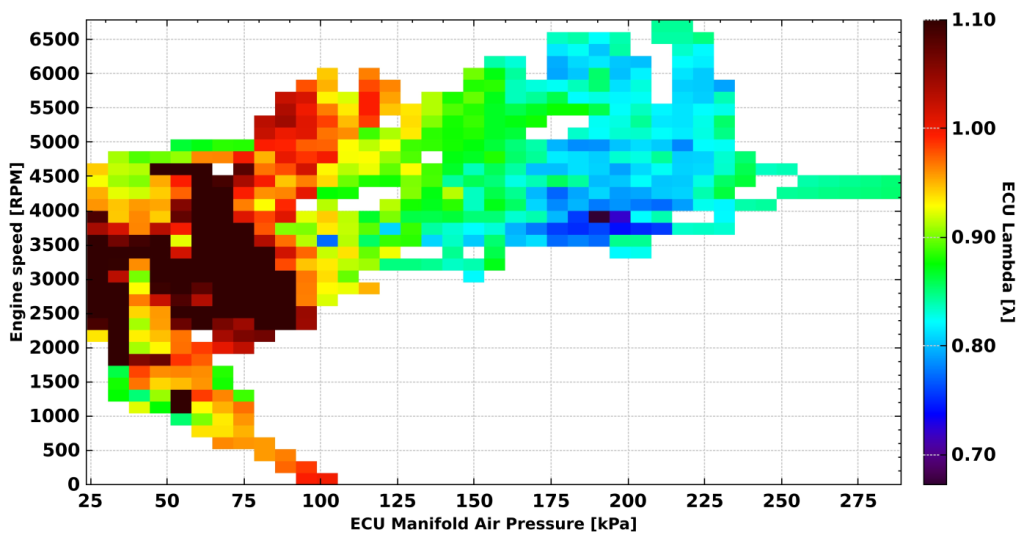

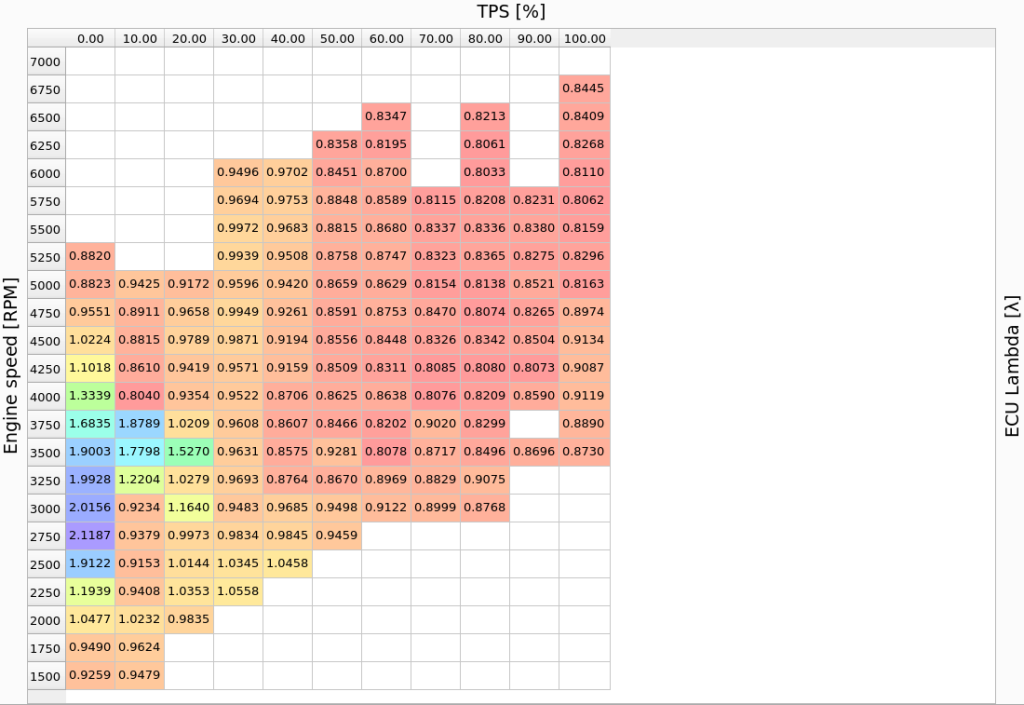

- Scatter plots – i.e. engine power as a function of ignition angle

- Flexible brake control modes: constant power, RPM lock, RPM limit, test sequences

- User-adjustable smoothing of graphs

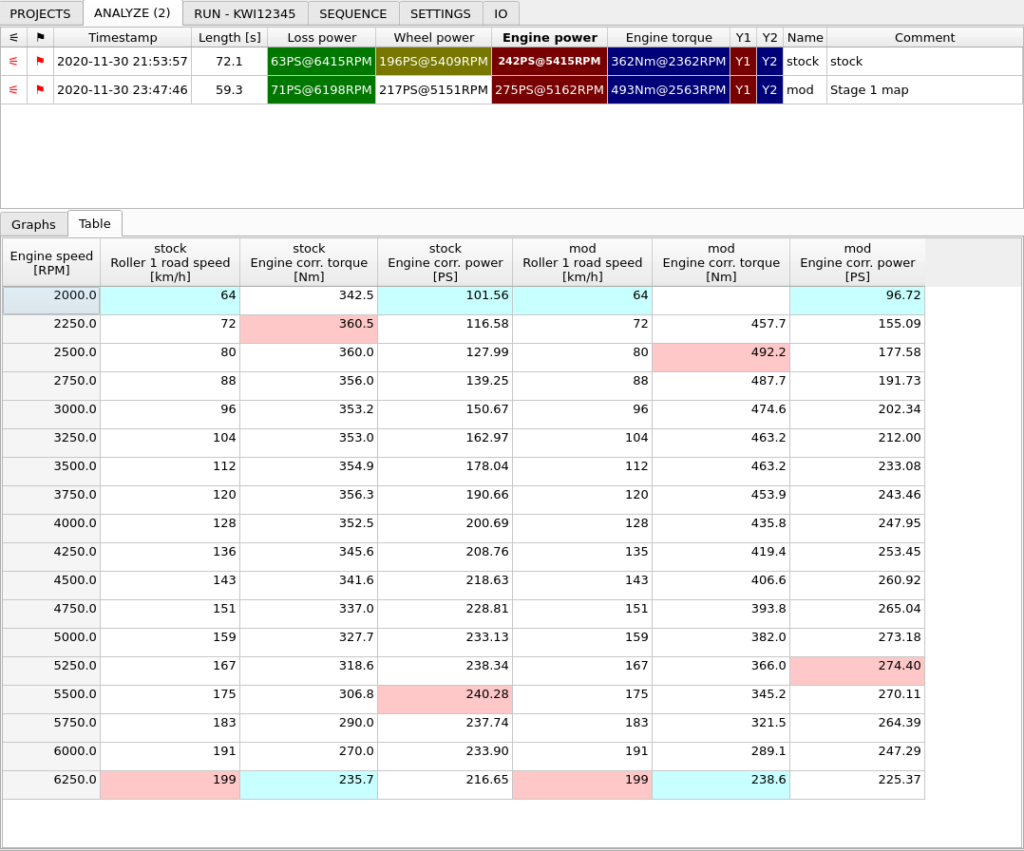

- Unlimited measurement compare function

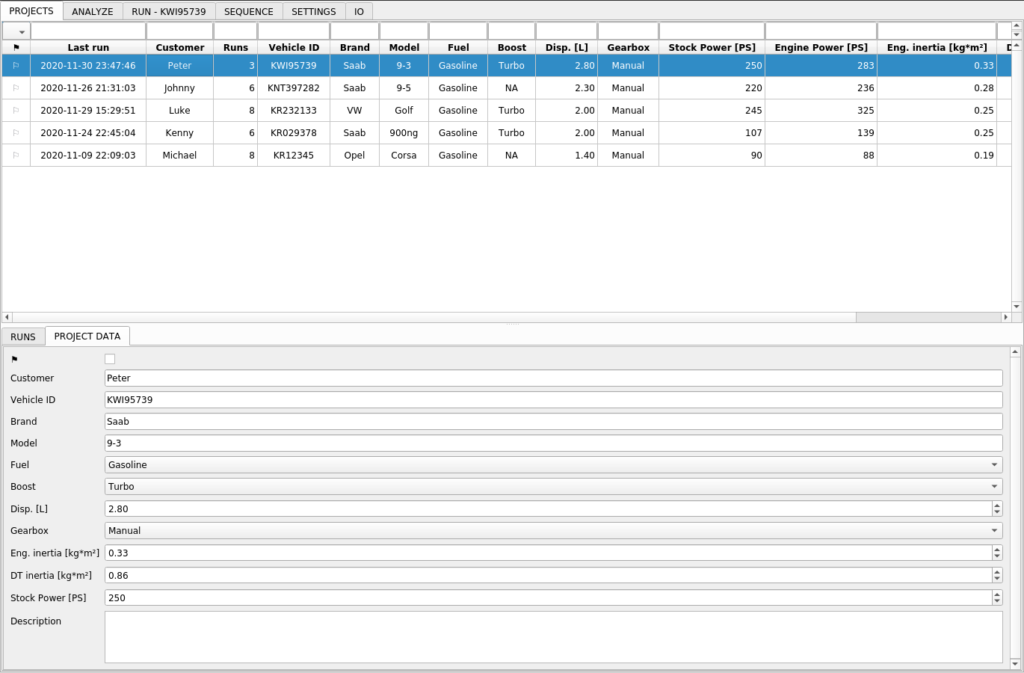

- Easy project and measurement management, project database

- Measurements saved in HDF format for data analysis in external software e.g. MATLAB

- Possibility to export data to CSV (Excel) format

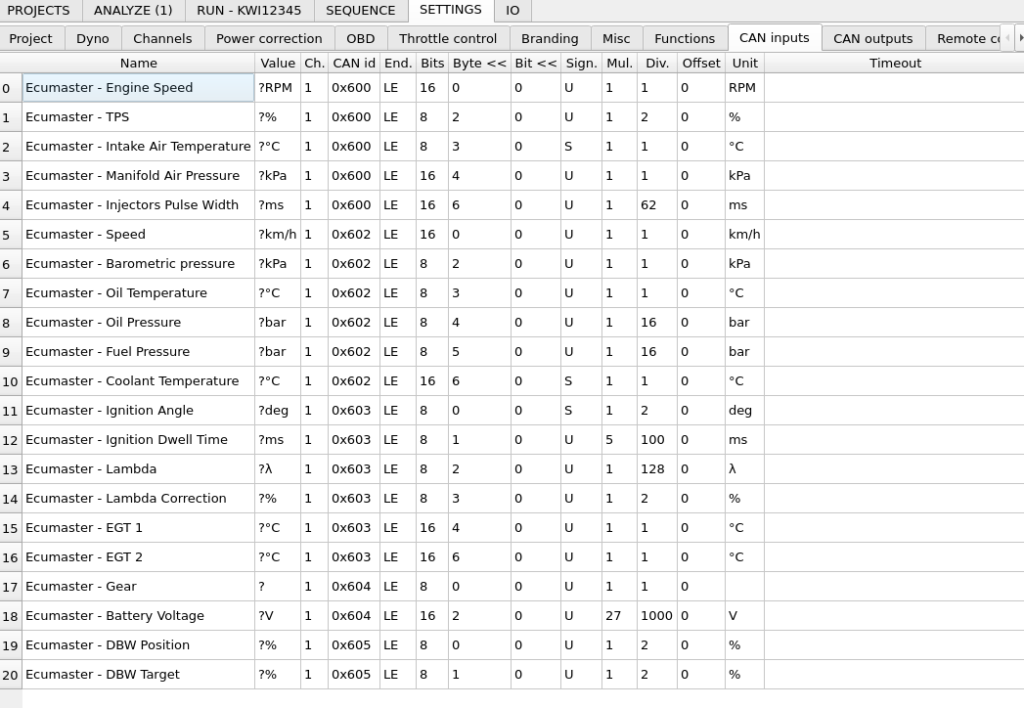

- Programmable data parsing from CAN bus, a lot of aftermarket ECU streams ready available

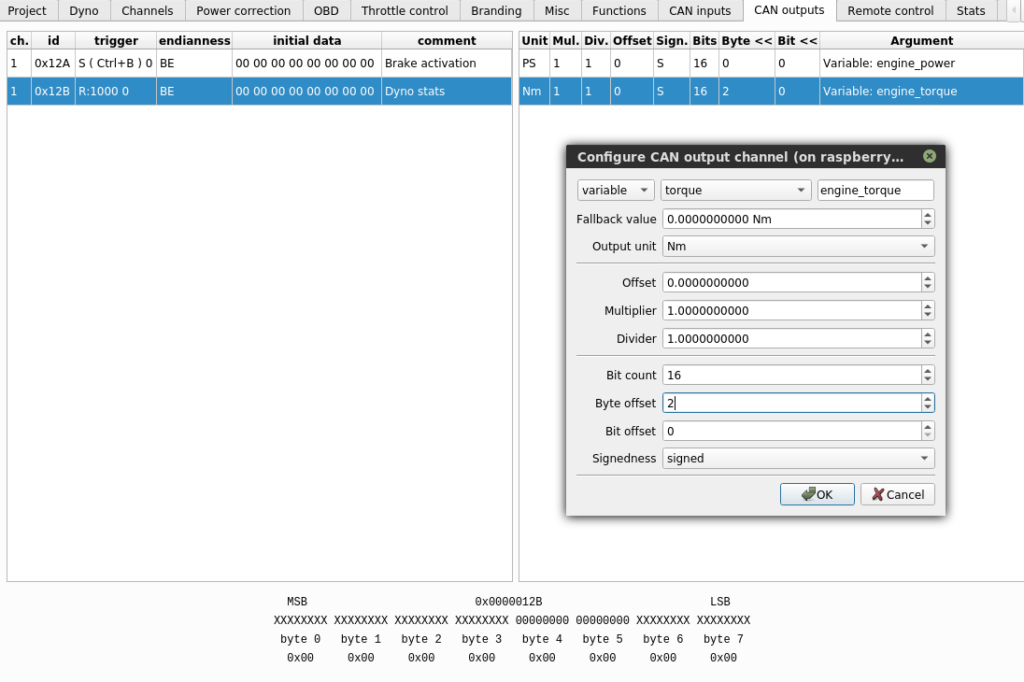

- Programmable CAN data export for interaction with other devices

- Possibility to extend the functionality of the device by modules connected via CAN bus – e.g. wideband lambda sensor controller

- Programmable logic to control device outputs based on all available data

All the documentation and videos presenting software features can be found in Help Section.