With the recent popularity rise of hub dynos, I often get asked which dyno is better: hub or chassis. The answer depends on the type of work you will be using the dyno for. Let’s start with a straight forward answer:

- Roller dyno – best for mainstream chip tuning and dyno days

- Hub dyno – best for professional motorsport and long tuning jobs on stand-alone ECUs.

- Engine dyno – best for engine builders for endurance testing and perfect measurement accuracy.

Now we can go into details of each dyno type and how I got to the short answer above. The main difference between these dyno types is the set-up time, power range and safety.

Roller dyno

This dyno type is the most popular and widely used among the tuning community. The biggest advantage of this dyno is short setup time. You drive onto it, strap the car down, and you’re ready to go. If you measure a lot of cars per day and do quick chip tuning, then it’s important not to spend too much time on setup.

The downside of the roller dyno is the work comfort in case of full day tuning jobs and issues with tires traction and safety with high power cars.

Hub dyno

The hub dyno is currently gaining popularity in professional tuning services. It is the solution to go, when the power of the vehicles you work on start to cause traction problems and safety hazard on roller dyno. The accuracy of this dyno type is better than the roller one, and it runs more quietly. The downside is the longer setup time due to the need to remove the wheels and attach the dyno hubs.

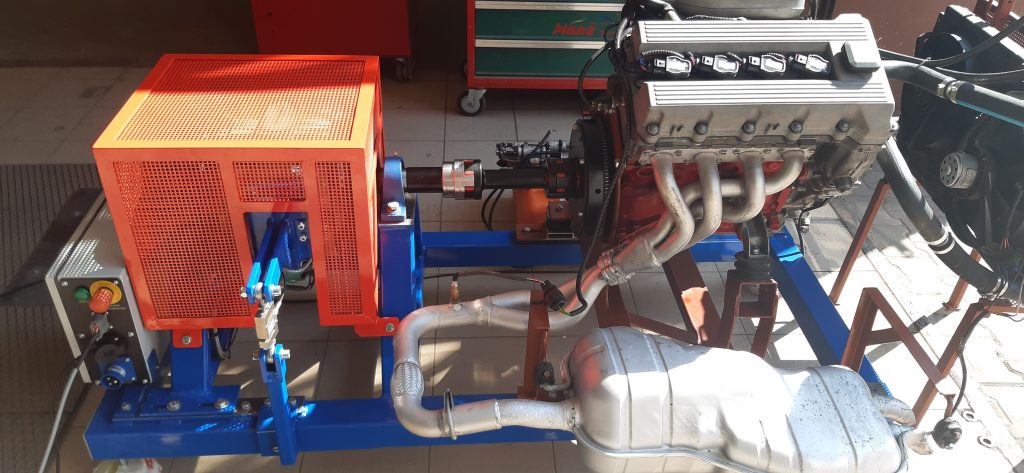

Engine dyno

This is the only dyno that accurately measures the engine power instead of estimating it from measured wheel power. It’s the one to go if you are an engine builder, and you already have the engine out of the vehicle chassis. Despite the setup of the engine on this dyno is the longest, it allows you to professionally and safely test and tune your engine build.

Final comparison table

| Roller dyno | Hub dyno | Engine dyno | |

|---|---|---|---|

| Vehicle set up time | 10-30min | 15-45min | Few hours to full day |

| Safety | Often exposed rollers Risk of tire blow out on high speeds or powers | Very safe Restricted access to rotating parts | Very safe Engine is usually secured in a dyno cell separate from operator |

| Comfort / Noise | Tire to roller contact is noisy Car on the dyno canstill vibrate | No tire noise but some vibration possible | With good sound insulation, the control room can be quiet and comfortable |

| Repeatability | Good | Very good | Perfect |

| Accuracy | Good with advanced software | Very good with advanced software | Perfect |

| Power range | 500PS per axle easily, 1000PS per axle on the limit of traction and safety, More can be achieved by increasing vehicle pressure on the rollers with straps or weights | No limit | No limit |

| Vehicle compatibility | AWD dyno with mechanical synchronization works with most vehicles | Some vehicle systems can cause problems |