Configuration for BD1 power supply and eddy current brake:

- Mode – duty cycle modulation

- Source – torque controller n output

- Frequency – 2000Hz

- Min duty cycle – 0%

- Max duty cycle – maximum braking force percent

For water brake with ON / OFF type water valve frequency should be lower:

- Frequency – 2Hz

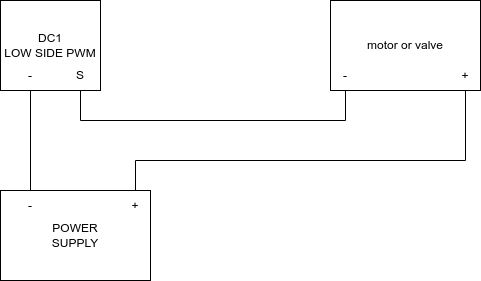

Connection schematic for devices requiring external power supply

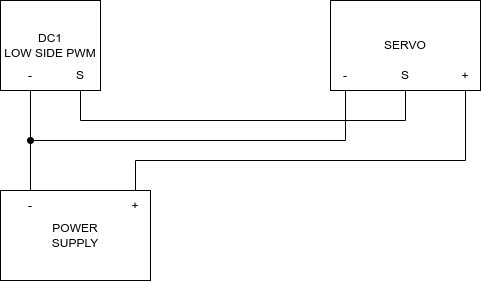

RC servo wiring diagram

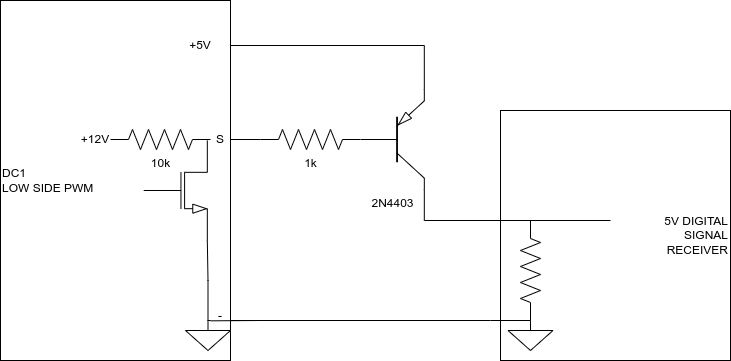

Signal inversion for receiver requiring high side signal

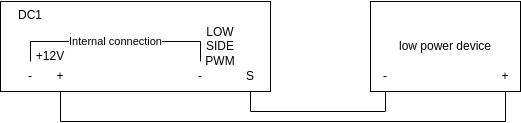

Using internal power supply for low power devices

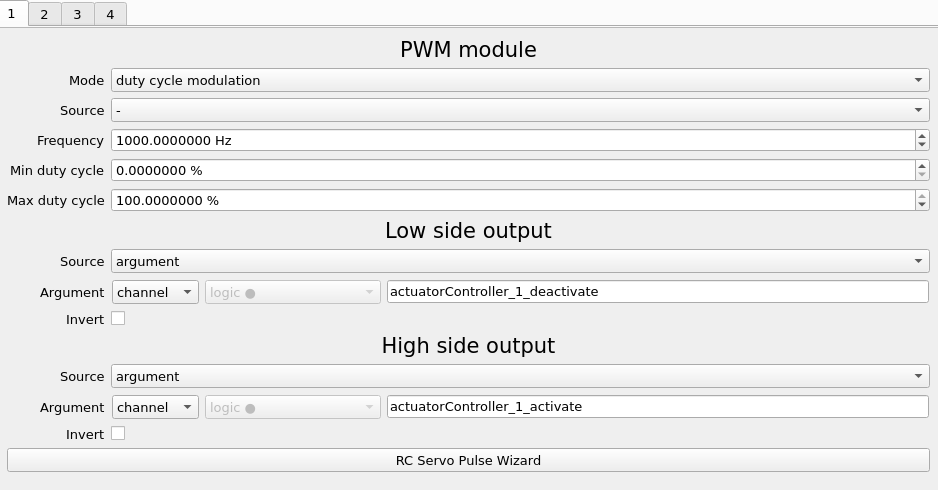

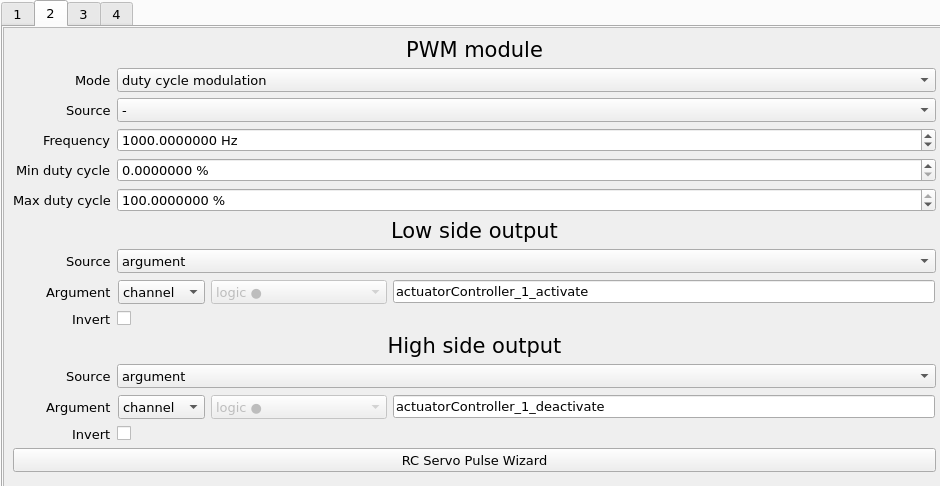

DC2 bidirectional DC motor control – one supply, two bridges

Example configuration for actuator control in both directions:

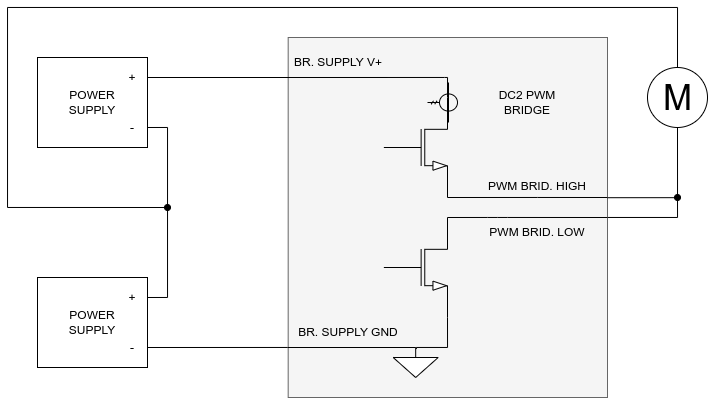

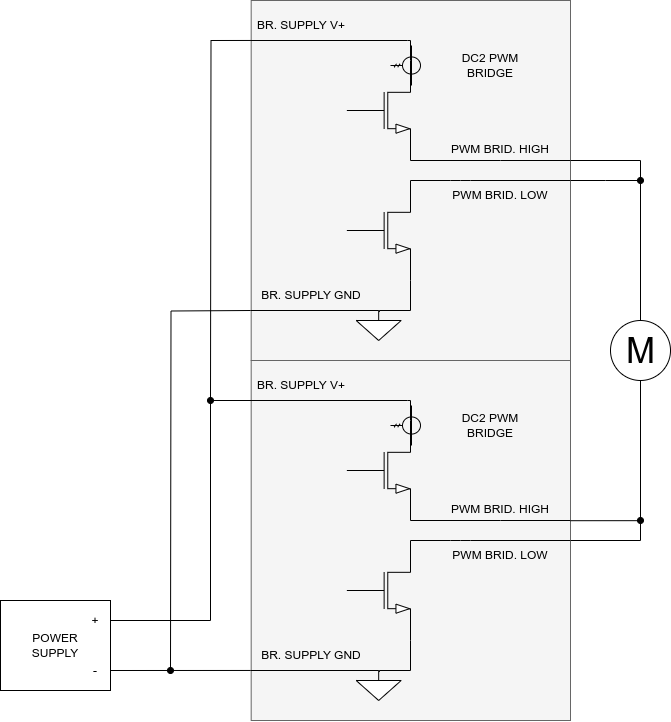

DC2 bidirectional DC motor control – two supplies, one bridge

This configuration allows controlling DC motor in two directions with use of only one PWM half bridge in DC2 per motor. This way you can control up to 4 motors from one DC2 controller.

‘-‘ in the top supply must not have a connection with ‘-‘ in the bottom supply to avoid short circuit.

Total bridge supply voltage must not exceed 28V.

Remember that current measurement is available on the high side of the bridge, so turning off the motor based on current will be available only in one motor direction.